Pre Engineering Buildings

Pre Engineering Buildings

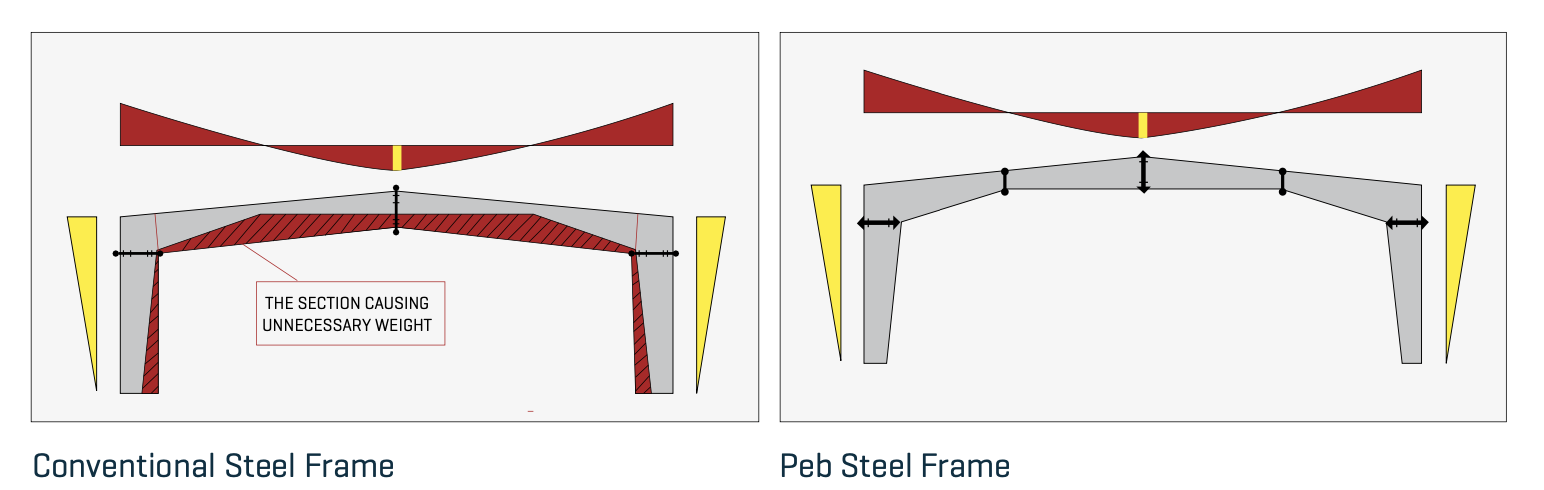

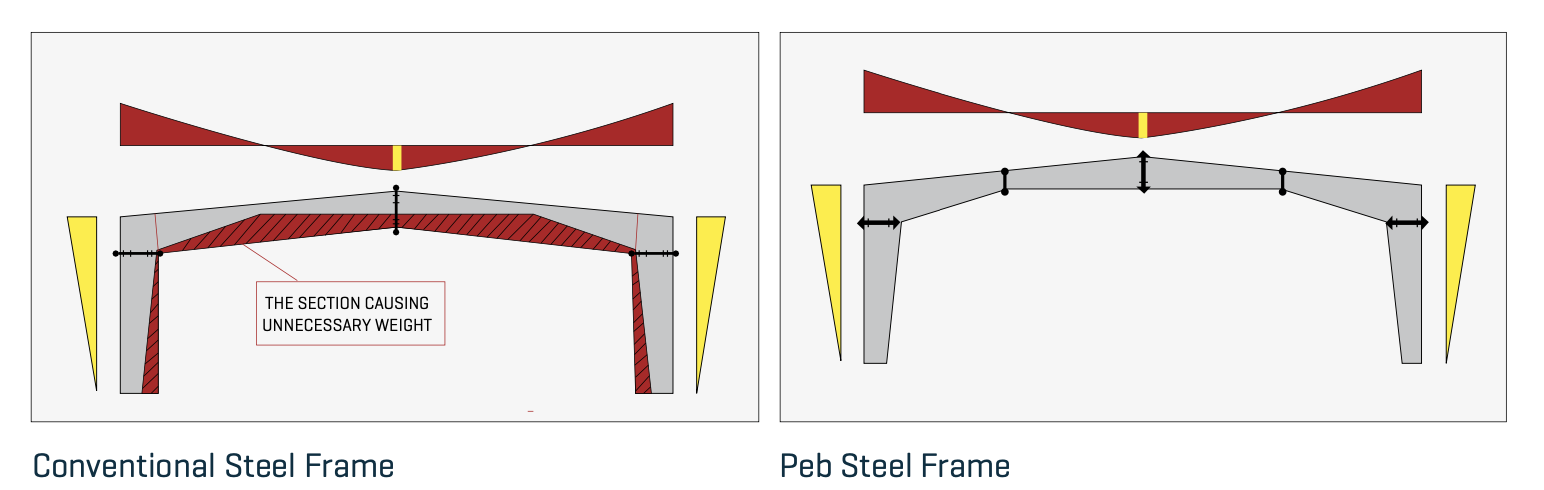

A Pre-Engineering Building (PEB) is a structure that is designed and fabricated using a set of standardized techniques and components, typically in a factory setting. These buildings are known for their efficiency, cost-effectiveness, and rapid construction. The use of PEBs has gained popularity in various industrial, commercial, and institutional sectors due to their numerous advantages.

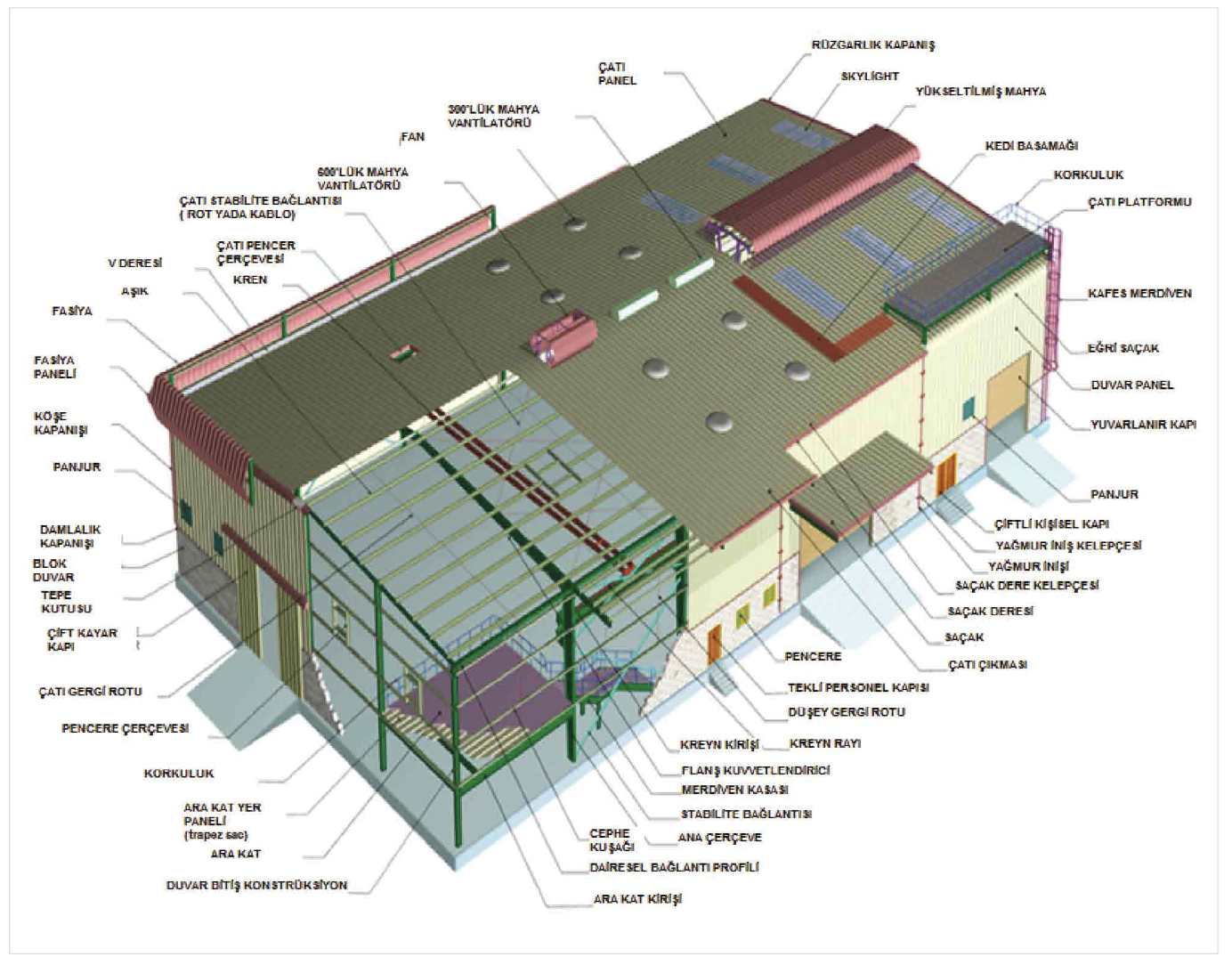

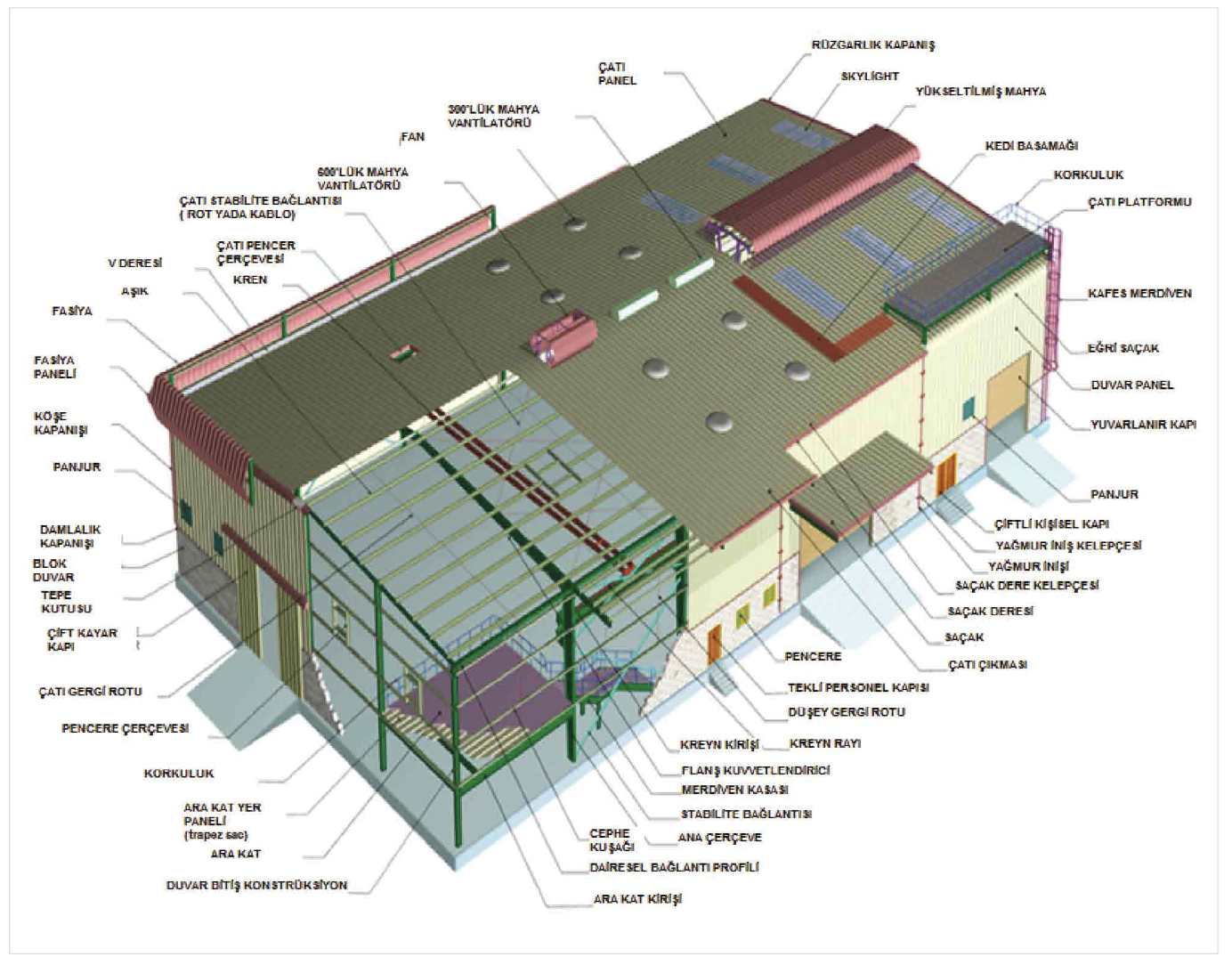

Key Components of a Pre-Engineering Building:

- Primary Framing:

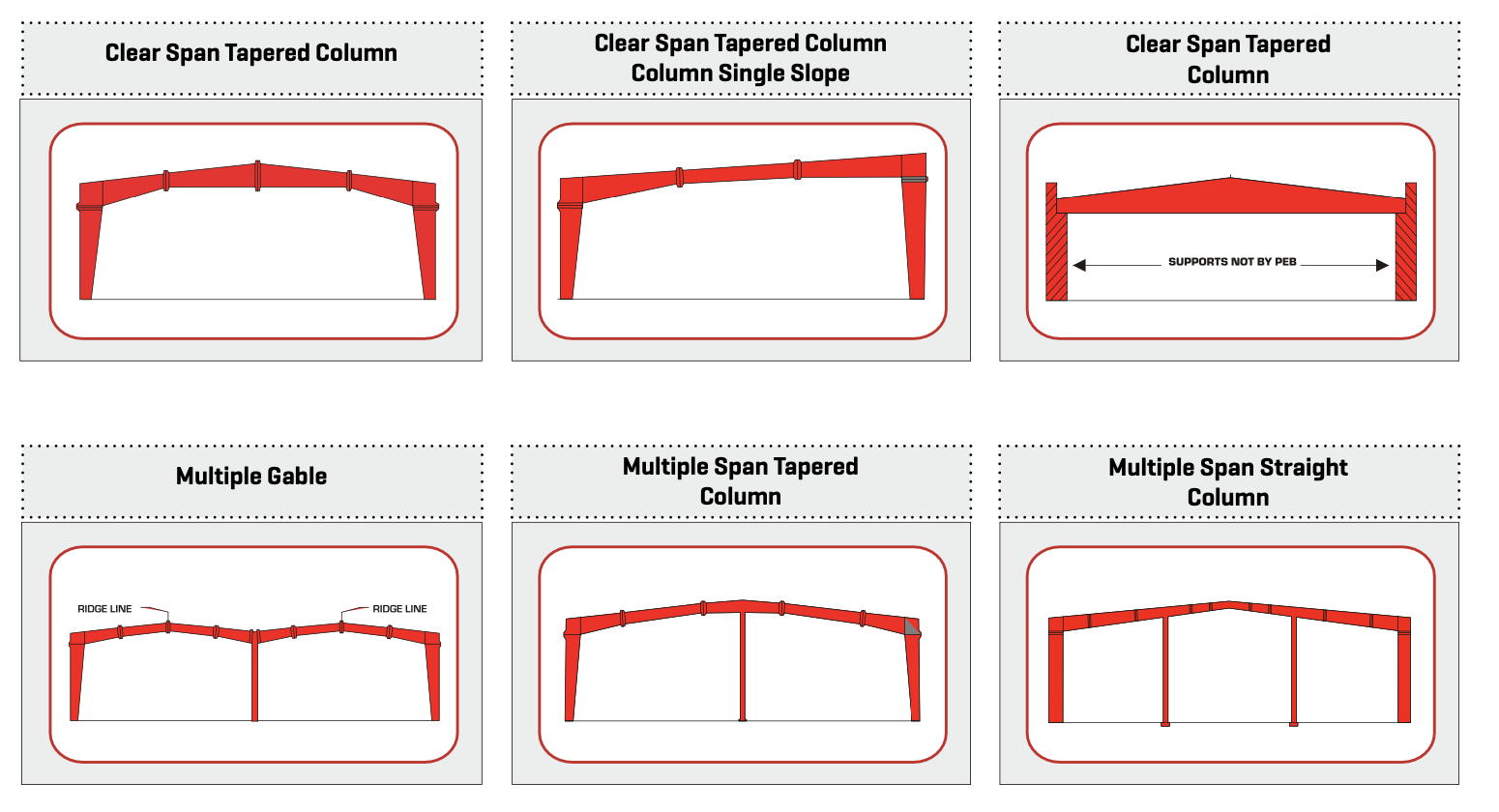

- The main structural components, including rigid frames, are pre-designed and manufactured. These frames are made of steel and serve as the skeleton of the building.

- Secondary Framing:

- Components like purlins, girts, and eave struts form the secondary framing. They provide additional support and stability to the structure.

- Roof and Wall Panels:

- PEBs typically use insulated metal panels for roofing and wall cladding. These panels are lightweight, durable, and contribute to the energy efficiency of the building.

- Crane Systems:

- For industrial applications, PEBs often incorporate crane systems that are designed to meet specific load requirements. These systems are integrated during the fabrication process.

- Doors and Windows:

- Openings for doors and windows are pre-determined in the design phase, and the building components are fabricated to accommodate them.

Advantages of Pre-Engineering Buildings:

- Cost-Effective:

- PEBs are generally more cost-effective than traditional construction methods due to the efficiency of the manufacturing process and reduced on-site labor requirements.

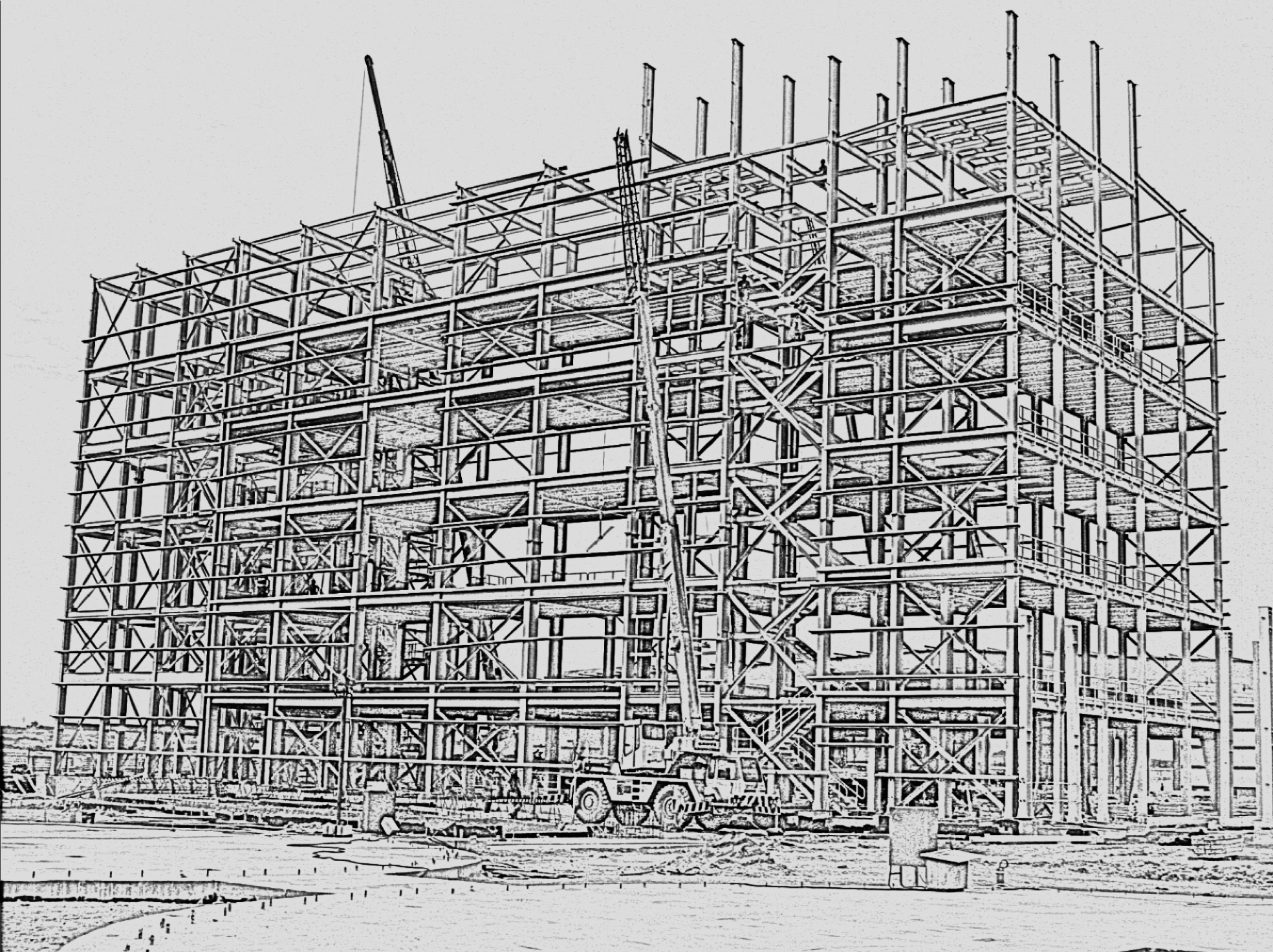

- Speed of Construction:

- The majority of the building components are pre-fabricated, leading to faster construction times compared to conventional building methods.

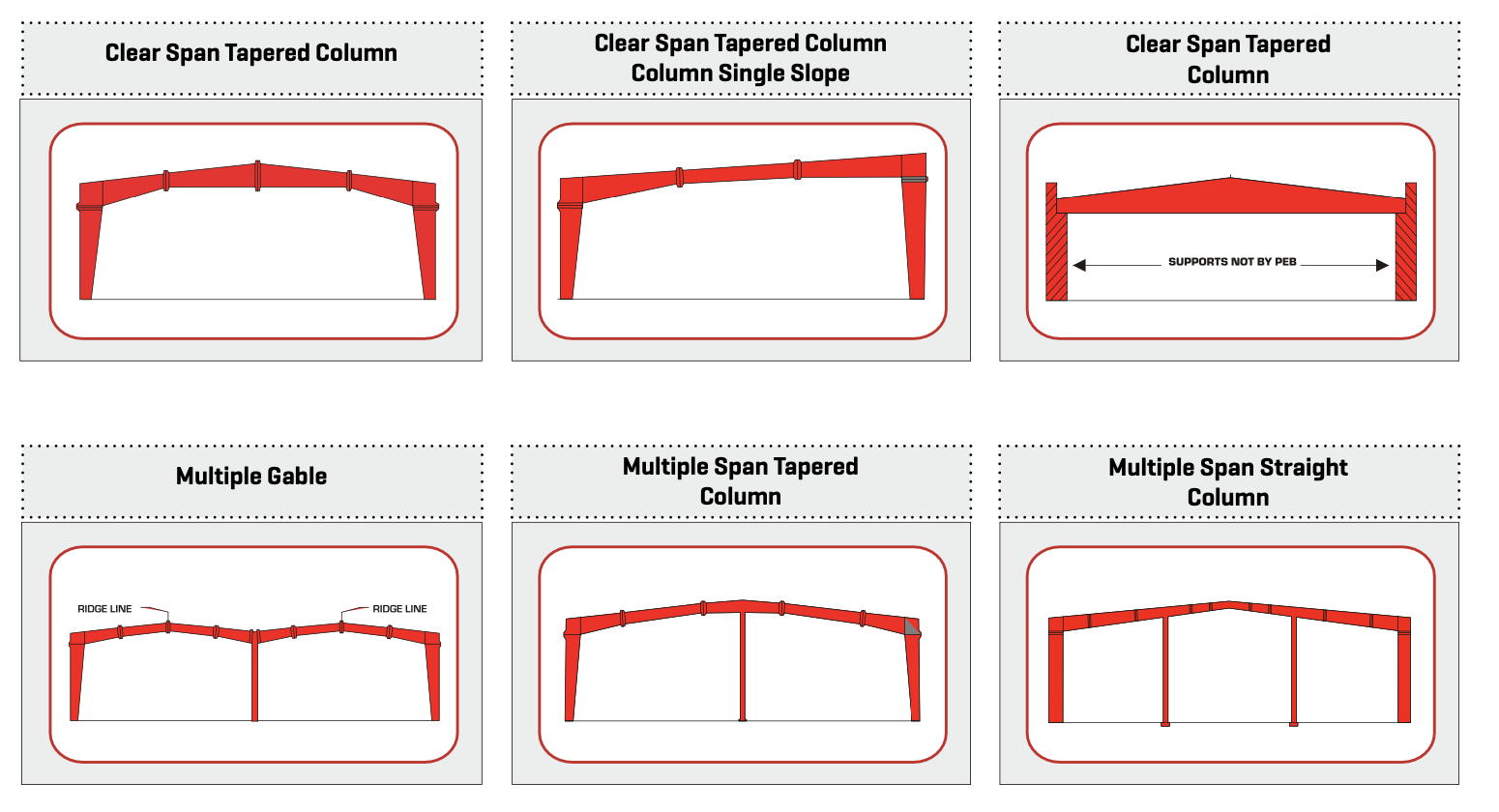

- Design Flexibility:

- PEBs offer design flexibility, allowing for customization based on the specific needs and requirements of the client. This makes them suitable for a variety of applications.

- Energy Efficiency:

- The use of insulated metal panels contributes to energy efficiency, providing better insulation and reducing overall energy consumption.

- Quality Control:

- The manufacturing process in a controlled environment ensures a high level of quality control, resulting in consistent and reliable structures.

-

Applications of Pre-Engineering Buildings:

Applications of Pre-Engineering Buildings:

- Industrial Warehouses and Factories:

- PEBs are commonly used for constructing industrial facilities due to their quick construction and cost-effectiveness.

- Commercial Buildings:

- Offices, retail spaces, and other commercial structures can benefit from the speed and efficiency of PEB construction.

- Agricultural Buildings:

- PEBs are suitable for constructing barns, storage sheds, and other agricultural facilities.

- Institutional Buildings:

- Schools, hospitals, and other institutional structures can be efficiently constructed using pre-engineered building systems.

In conclusion, Pre-Engineering Buildings offer a modern and efficient approach to construction, making them a popular choice for a wide range of applications. Their cost-effectiveness, speed of construction, and adaptability to various designs contribute to their widespread use in the construction industry.

Pre Engineering Buildings

Pre Engineering Buildings

Applications of Pre-Engineering Buildings:

Applications of Pre-Engineering Buildings: